Knowledge, Experience, and Technology to achieve the best Comfort

Men and Machines. Tradition and Innovation.

Each Calia Italia product is the result of the combination of different excellences, inspired by tradition, devoted to innovation. Calia Italia sofas are characterized by careful and meticulous craftsmanship. Each element can be considered a unique piece, because it is made by human hands and therefore identical to no other.

CONCEPTION AND DESIGN

Each new product is conceived by the designers at the Calia Italia Study Center after careful analysis of new trends, desires, and needs of different markets.

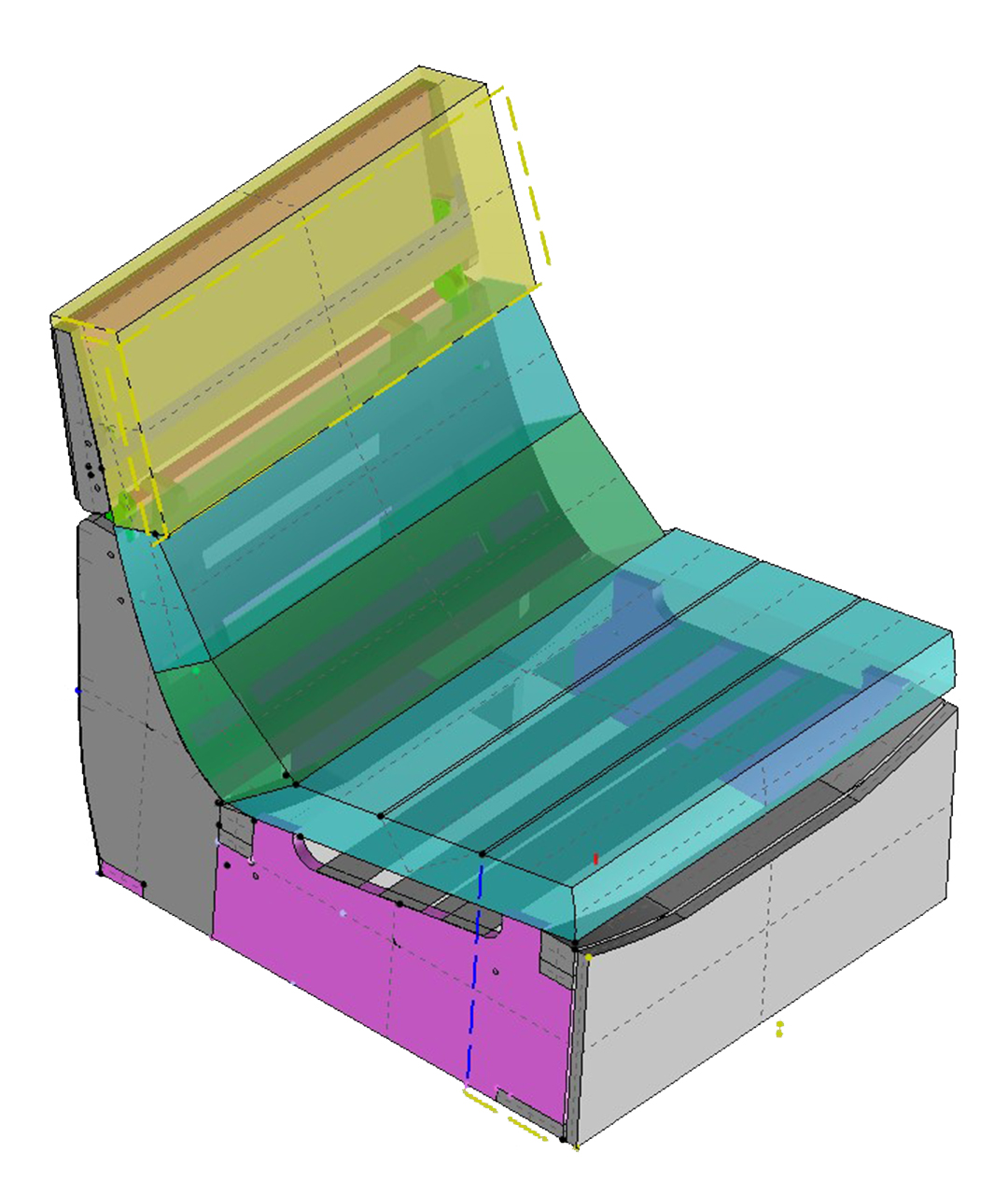

VIRTUAL PROTOTYPING

Thanks to an innovative virtual prototyping and product development software, the design of the new model is simulated virtually, evaluating all possible design alternatives to find a compromise that meets style, industrialization, and cost constraints before moving on to the actual prototyping phase.

MANUFACTURING OF SEMI-FINISHED COMPONENTS

Following the technical specifications provided by the Calia Italia Study Center, wood and polyurethane are shaped to create, respectively, the load-bearing structure - the frame - and the sofa's padding.

BELT ASSEMBLY AND WHITE LINING

Belt assembly is the phase in which elastic straps are applied to the seat and backrest of the frame to accommodate and support the padding. The addition of these is called "white lining”

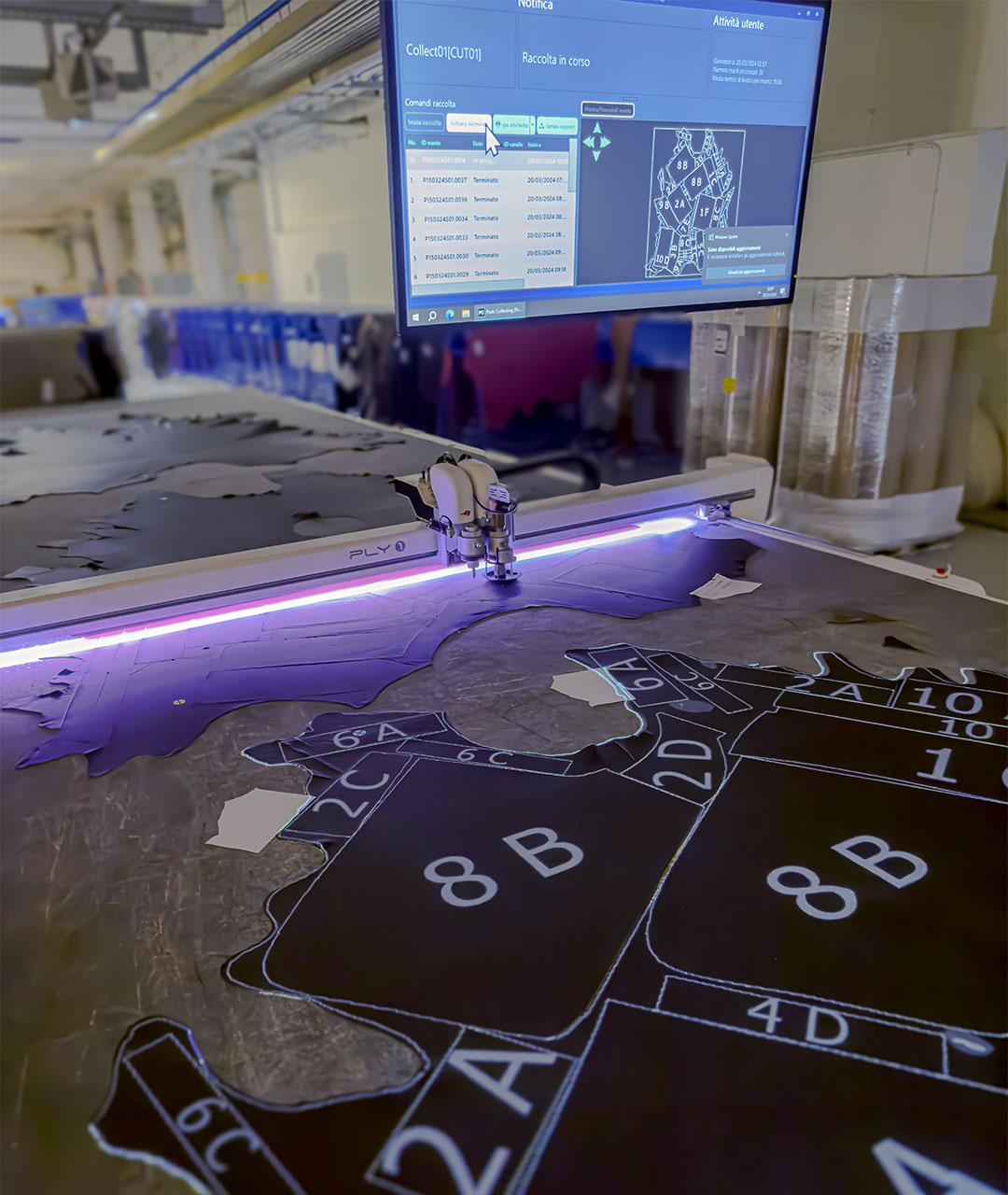

CUTTING

High-performance machinery for automated fabric cutting and scanning, as well as automated leather cutting, ensure maximum quality. However, especially concerning leather, the craftsmanship know-how remains irreplaceable. Each leather hide is unique in its shape and distribution of quality zones, thus not allowing for a standardized process, but requiring specific and unique work for each hide.

SEWING

It's a highly detailed process. The cut and shaped parts are then assembled according to a very detailed technical pattern.

ASSEMBLY

The components that bring the finished product to life are assembled: frame, padding, sewn covering, feet, and any mechanical and electrical components.

VERIFICATION AND QUALITY CONTROL

Each stage of production undergoes rigorous checks to verify product compliance, adherence to design specifications, and what is established in the order confirmation.

PHOTOGRAPHY ROOM

The sofa is ready to be photographed and is brought to the assembly room, a space of over 500 square meters designed by architect Saverio Calia to accommodate photographic shoots and video productions of sofas and armchairs directly in the company. A modular space that allows the setup of any type of set, whether it's advertising photos, images for catalogs, shots with models, or still life.

PACKAGING

Each sofa is 'packaged' with an informative brochure attached to guide our customers in understanding its use and maintenance. Each labeled product is packed and stored in the automated warehouse, accompanied by a document that allows the recognition of the origin of each individual part through codes.

SHIPPING AND TRANSPORT

All our products are transported with the utmost care by road and by sea in special, rationalized containers, which are also 'padded', to comfortably reach our customers all over the world, with precise timing and in perfect condition. Wherever they may be.

AFTER-SALES SERVICE

The Customer Care activity at Calia Italia ensures assistance to customers both before and after the sale. Thanks to the traceability of materials and suppliers for each of our products, we are able to provide suitable solutions for all needs even years after the sale.